Automate Efficient Material Allocation.

Material Inventory

Optimization Solution

Optimal Material Distribution with Automation.

Reducing waste and optimizing inventory is key to your organization’s operational success.

Our solution empowers your team to fulfill orders with maximum efficiency by leveraging complete on-hand inventory and stock insights with built-in logic specialized for your business.

Reduced Waste + Reduced Costs

Minimize costs associated with excess inventory and waste, freeing up capital for other business initiatives.

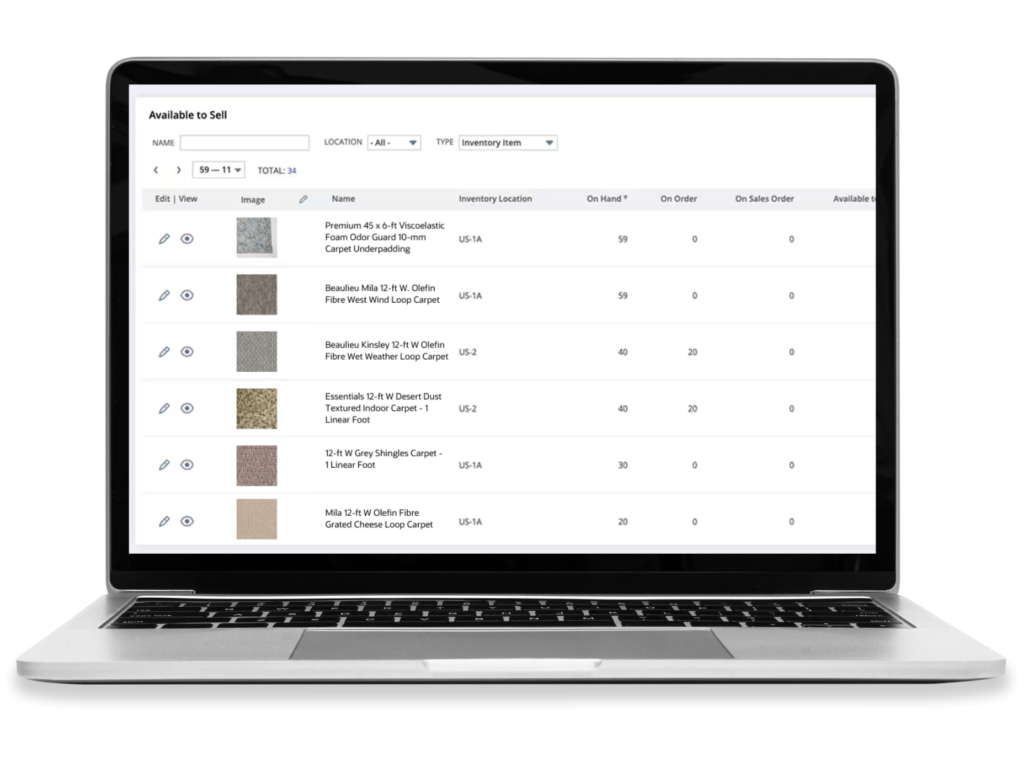

Optimized Order Fulfillment

Procedurally generate the best combination of existing lot numbers based on the required quantity.

Efficient Material Matching

Automate matching of various inventory variables such as weight, type, color, and dye lot for optimal order combinations.

Key Features

-

Boosted Profitability

Boost your bottom line with reduced costs attributed to waste from sub-optimal material allocation.

-

Reduction in Waste

Reduce your organization's environmental footprint by ensuring more inventory materials are used.

-

Remnant Optimization

Automate the selection process for remnant materials for future batches and orders.

-

Enhanced Scalability

As your business grows, optimized inventory processes ensure the ability to meet fluctuating demand.

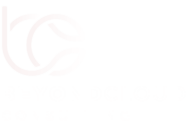

All Present and Accounted For.

Fulfill orders using the most suitable materials for each specific order, right down your preferred unit of measure and the variables that define your products, effectively minimizing wastage.

Reduce unnecessary usage while increasing your bottom line with optimal material allotment all within NetSuite.

Industry Applications